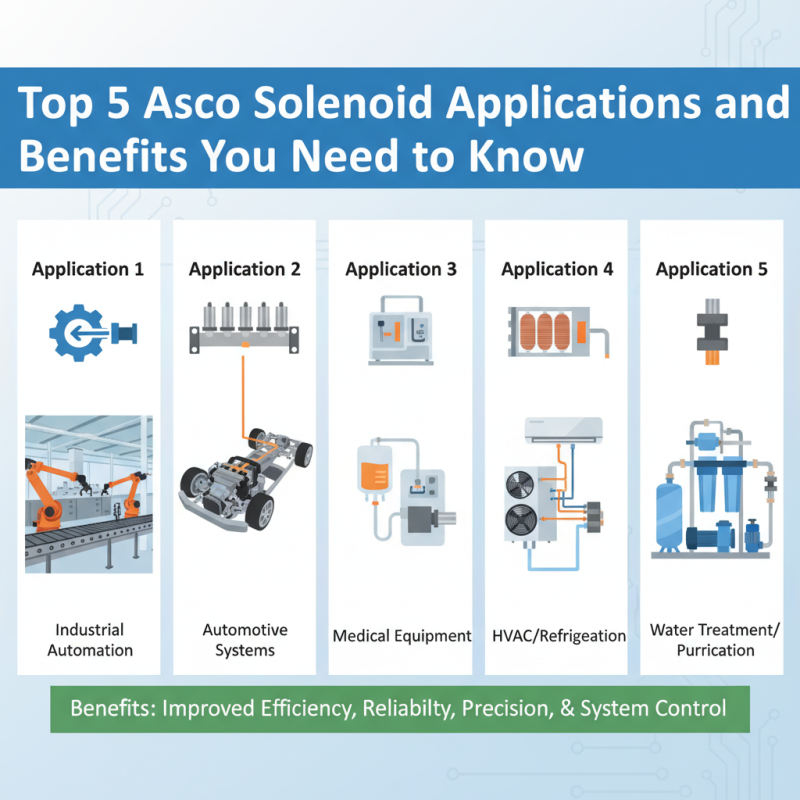

Top 5 Asco Solenoid Applications and Benefits You Need to Know

When it comes to automation and control systems, the role of asco solenoid valves cannot be overstated. These versatile devices are pivotal in various applications, providing reliable performance and excellent efficiency across numerous industries. Asco solenoids are electromagnetic devices that control the flow of liquids and gases in pneumatic and hydraulic systems, making them essential components in modern machinery and equipment.

In this article, we will explore the top five applications of asco solenoids and highlight the benefits they bring to different sectors. From simple on/off functions to complex control operations, asco solenoids are designed to enhance operational efficiencies and simplify system management. Understanding these applications will not only provide insight into the versatility of asco solenoids but also illustrate how they contribute to improving productivity and reliability in industrial settings. Whether you are involved in manufacturing, automotive, or any other field requiring precise fluid control, knowing the benefits of asco solenoids can help you make informed decisions for your operations.

Overview of Asco Solenoids and Their Functionality

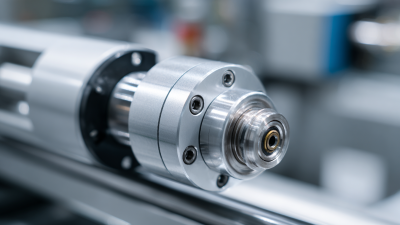

Asco solenoids are integral components widely used in various industries for their reliable functionality in controlling fluid flow and automation processes. A solenoid operates by converting electrical energy into mechanical movement, utilizing a coil of wire wound around a metal core. When an electric current passes through the coil, it creates a magnetic field that either opens or closes a valve, thus regulating the flow of liquids or gases. This fundamental principle allows for enhanced precision and efficiency, making solenoids an essential element in systems ranging from hydraulic equipment to HVAC applications.

Industry data underscores the significance of solenoids in automating processes, with a report from a leading research firm indicating that the global solenoid market is expected to grow by approximately 6% annually over the next five years. The versatility of these devices is evident across multiple applications, such as industrial machinery, medical devices, and transportation systems. For instance, in pneumatic control systems, solenoids contribute to reduced energy consumption and improved operational safety by ensuring immediate response times. Furthermore, advancements in solenoid technology, including improved materials and designs, are enhancing their durability and performance, thereby increasing their adoption across diverse sectors. This trend not only boosts operational efficiency but also contributes to sustainable practices within industries that prioritize environmental responsibility.

Key Industries Utilizing Asco Solenoid Valves

Solenoid valves have become essential components across various industries, providing efficient control and automation in systems involving fluid dynamics. Notably, sectors such as food and beverage, pharmaceuticals, and manufacturing are leveraging these devices for their reliability and precision. According to a recent report from the Global Solenoid Valve Market, the demand for these components is projected to grow at a CAGR of 4.5% from 2023 to 2030, signifying their critical role in modern industrial applications.

In the food and beverage industry, Asco solenoid valves are utilized for controlling fluid flow in processes such as bottling and packaging. Their ability to ensure a clean and sanitary operation meets stringent health standards while optimizing production time. Similarly, the pharmaceutical industry benefits from the application of these valves in drug manufacturing processes, where precision and control are paramount for maintaining product integrity.

Tip: When selecting solenoid valves for applications in sensitive industries, consider valves with certifications for safety and compliance to ensure they meet industry standards. In the manufacturing sector, where automation is key, solenoid valves can streamline operations, reduce manual labor, and enhance system efficiency. Reports indicate that automating fluid control systems could lead to a reduction in operational costs by up to 25%, further underscoring the importance of integrating these valves into modern industrial practices.

Top 5 Asco Solenoid Applications and Benefits You Need to Know - Key Industries Utilizing Asco Solenoid Valves

| Application | Industry | Benefits |

|---|---|---|

| Fluid Control | Manufacturing | Precise control over fluid flow enhances production efficiency. |

| Automated Dispensing | Food & Beverage | Consistency in portioning reduces waste and improves quality. |

| Gas Flow Management | Oil & Gas | Enhanced safety and precision in handling gases. |

| HVAC Systems | Construction | Improved energy efficiency and comfort control. |

| Irrigation Control | Agriculture | Optimizes water usage and promotes sustainable practices. |

Top 5 Applications of Asco Solenoids in Various Sectors

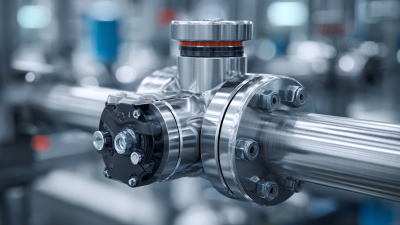

Asco solenoids are widely utilized across various sectors due to their reliability and effectiveness in controlling fluid power and automation systems. In the manufacturing industry, these solenoids play a crucial role in operating pneumatic and hydraulic valves, ensuring precise control over the movement and distribution of fluids. This application not only enhances operational efficiency but also contributes to improved safety by preventing mishandling of materials.

In the automotive sector, the integration of solenoids in fuel and exhaust systems has led to significant advancements in vehicle performance and emissions control. These solenoids are pivotal in managing fuel injection processes and optimizing airflow, which directly impacts engine efficiency. Additionally, in the HVAC industry, solenoids are essential for controlling refrigerant flow and regulating temperatures, thereby fostering energy efficiency and comfort in heating and cooling systems.

Moreover, the agricultural field benefits from solenoid applications in irrigation systems. By automating the water supply process, these devices allow for precise control over irrigation schedules, ensuring crops receive adequate moisture while minimizing water waste. As technology continues to evolve, the versatility of solenoids will likely lead to even broader applications across various industries, enhancing productivity and sustainability.

Top 5 Applications of Asco Solenoids in Various Sectors

This chart illustrates the relative frequency of Asco solenoid applications across different sectors, highlighting the automotive industry as the most prevalent, followed by manufacturing and HVAC applications.

Benefits of Implementing Asco Solenoids in Automation Systems

Implementing solenoids in automation systems brings a wealth of benefits that enhance efficiency and reliability in various applications. One of the primary advantages is their precision in controlling fluid and pneumatic systems. Solenoids offer rapid response times and precise actuation, enabling automated processes to operate seamlessly. This capability ensures that operations maintain optimal flow and pressure, significantly improving system performance and reducing waste.

Another key benefit is the reduction of manual intervention in automation. By utilizing solenoids, systems can be designed to operate autonomously, minimizing the need for human oversight. This not only improves safety by lowering the risk of human error but also allows personnel to focus on more strategic tasks, ultimately leading to increased productivity. Additionally, solenoids are known for their durability and low maintenance requirements, which contribute to reduced operational costs over time.

Moreover, the versatility of solenoids means they can be integrated into a wide range of automation applications, from industrial machinery to HVAC systems. Their compact design allows for easy installation and flexibility in various configurations, making them an ideal choice for modern automated environments. This adaptability ensures that businesses can scale their systems efficiently without significant additional investment.

Future Trends in Asco Solenoid Development and Usage

As the demand for automation and energy efficiency continues to rise, the development and application of solenoid technology are evolving rapidly. Future trends indicate a significant shift towards more compact, energy-efficient solenoids with enhanced control capabilities. Innovations in materials and design will allow for solenoids that consume less power while delivering greater performance. Additionally, advancements in digital technology will pave the way for smarter solenoid systems that integrate seamlessly with IoT devices, allowing for real-time monitoring and control.

Tips for selecting the right solenoid include considering essential factors such as the required force output, response time, and environmental conditions. This knowledge can significantly impact the efficiency and longevity of the solenoid application. Furthermore, staying informed about up-and-coming technologies will help users make more strategic decisions, ensuring that their solenoid solutions remain relevant and effective amidst changing industry standards.

The integration of machine learning and AI in solenoid design is another exciting development on the horizon. These technologies will enable predictive maintenance, reducing downtime and enhancing system reliability. Understanding these trends can empower decision-makers to invest in future-ready solenoid applications that not only meet current operational needs but also adapt to future challenges.

Related Posts

-

Maximizing Efficiency with Asco Solenoids in Modern Automation Systems

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

Understanding the Importance of Flow Control Valves in Modern Industrial Applications

-

Top 10 Benefits of Using Globe Valves in Industrial Applications

-

Exploring the Future of Valve Automation and Control in Sustainable Energy Solutions

-

Understanding Natural Gas Valves: Essential Guide to Safety and Efficiency in Your Home