The Best 10 Pressure Control Valve Models for Optimal Performance?

In the world of industrial applications, the pressure control valve plays a crucial role. These devices regulate fluid pressure, ensuring safety and efficiency. Industry expert Dr. Alice Smith emphasizes, "Choosing the right pressure control valve can transform operational efficacy."

Pressure control valves come in various models, each tailored for specific needs. This diversity presents both opportunities and challenges. For instance, selecting a model that suits your system can be complex. It’s essential to assess performance metrics critically. Some valves may promise high efficiency but lack reliability in specific conditions.

Moreover, the installation and maintenance of pressure control valves demand attention. Poor installation can lead to failure. Understanding the intricacies involved is vital for optimal performance. The best choices require careful deliberation, yet industry standards often leave room for improvement. Adapting to changing demands is necessary for sustained success.

The Importance of Pressure Control Valves in Industrial Applications

Pressure control valves play a vital role in industrial processes. They regulate fluid flow and maintain desired pressure levels. According to a report by the International Society of Automation, improper pressure control can lead to equipment failures or inefficient operations. In fact, nearly 20% of all industrial downtime is due to inadequate pressure management.

In applications such as oil and gas, precise pressure control is crucial. A small deviation can result in costly leaks or operational hazards. Data from the American Petroleum Institute indicates that more than 30% of accidents are linked to pressure regulator failures. This emphasizes the need for high-performance pressure control valves.

Despite advancements in technology, challenges remain. Many facilities still rely on outdated systems. These can be prone to faults, which can escalate maintenance costs. Regular testing and evaluation of pressure control systems are essential. Often, organizations lack the proper protocols to assess their valves' performance. Addressing these gaps can enhance safety and efficiency in operations.

Key Specifications to Consider When Selecting Pressure Control Valves

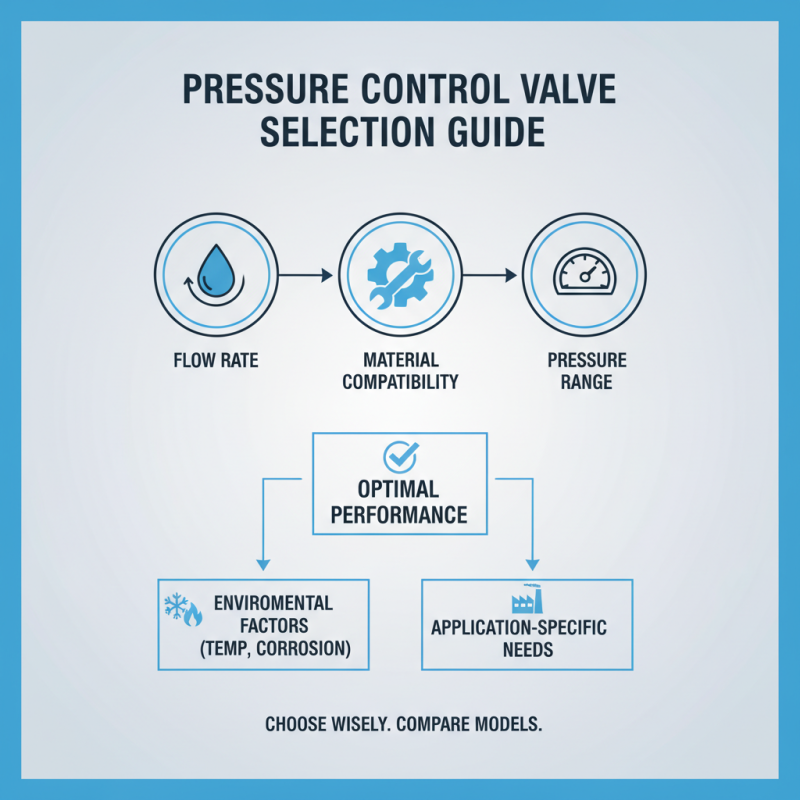

When selecting pressure control valves, key specifications are crucial. Consider the valve's maximum pressure rating. It defines the safe operating limits. Improper ratings may lead to failures. Also, check the flow capacity. A valve that can't handle the required flow can cause issues in operations.

Another essential factor is the material construction. Different materials resist corrosion differently. If you're dealing with a harsh environment, choose wisely. Additionally, the valve type matters. Spring-loaded valves may work better in certain applications than pilot-operated ones. Understanding these nuances can help avoid costly mistakes.

Lastly, consider the response time. A slow valve may not meet your system's needs. Some projects may overlook such details. Evaluating your requirements thoroughly is necessary. Pressure control valves play a vital role in system performance. Don't rush this decision. Reflect on your system's demands before making a choice.

The Best 10 Pressure Control Valve Models for Optimal Performance

| Model | Pressure Range (psi) | Material | Size (inches) | Connection Type | Weight (lbs) |

|---|---|---|---|---|---|

| Model A | 0-150 | Stainless Steel | 1" | Threaded | 5.5 |

| Model B | 0-200 | Brass | 1.5" | Flanged | 6.0 |

| Model C | 0-300 | Aluminum | 2" | Welded | 4.5 |

| Model D | 0-100 | Plastic | 1" | Threaded | 3.0 |

| Model E | 0-250 | Copper | 2" | Flanged | 8.0 |

| Model F | 0-150 | Stainless Steel | 1" | Threaded | 5.5 |

| Model G | 0-180 | Brass | 1.5" | Flanged | 6.0 |

| Model H | 0-360 | Aluminum | 2" | Welded | 4.5 |

| Model I | 0-90 | Plastic | 1" | Threaded | 3.0 |

| Model J | 0-220 | Copper | 2" | Flanged | 8.0 |

Top 10 Pressure Control Valve Models: Performance Metrics and Comparisons

Choosing the right pressure control valve is essential for optimal performance in various applications. Different models offer unique performance metrics, making it crucial to compare them thoughtfully. Many factors influence the choice—flow rate, material, and pressure range, to name a few. Some valves might excel in specific conditions but fail in others. It's important to consider the specific environment where the valve will operate.

For instance, a valve may demonstrate excellent precision in maintaining pressure. However, its responsiveness to sudden pressure changes could be lacking. In another case, some models may be robust but slower to react, impacting overall system efficiency. Performance metrics can vary significantly based on the application. Users must weigh these performance aspects against their operational needs. Testing several models under similar conditions may reveal surprising insights.

It’s not uncommon for users to overlook certain details. For example, compatibility with existing systems often gets ignored. Installation challenges can also arise, depending on the chosen model. Thus, while one valve might seem ideal, real-world performance can differ. Evaluating each valve's specifications against practical requirements will lead to more informed decisions.

Industry Standards and Certifications for Pressure Control Valve Models

Pressure control valves play a crucial role in various industries. Their performance can be significantly influenced by compliance with industry standards and certifications. According to recent data from the American Society of Mechanical Engineers (ASME), over 70% of pressure control valve failures are related to non-compliance with these standards. This highlights the importance of adhering to established guidelines.

The ISO 9001 certification is essential for manufacturers. It ensures consistent quality in production processes. A report from the International Organization for Standardization indicates that certified companies tend to have 20% fewer operational failures. Additionally, safety certifications such as API 527 are important. They confirm that valves can withstand extreme conditions. A significant percentage of users report increased confidence in safety when these certifications are present.

However, not all manufacturers achieve these standards. Sometimes, the rush to meet deadlines compromises quality. It's critical for industry professionals to prioritize thorough testing. A survey revealed that 15% of users encountered issues due to improperly certified valves. This underlines the need for vigilance in monitoring compliance with regulations. Keeping updated with industry standards can lead to better performance and reduced risk.

The Best 10 Pressure Control Valve Models for Optimal Performance

This chart displays the pressure ratings of the top 10 pressure control valve models, showcasing their optimal performance as per industry standards.

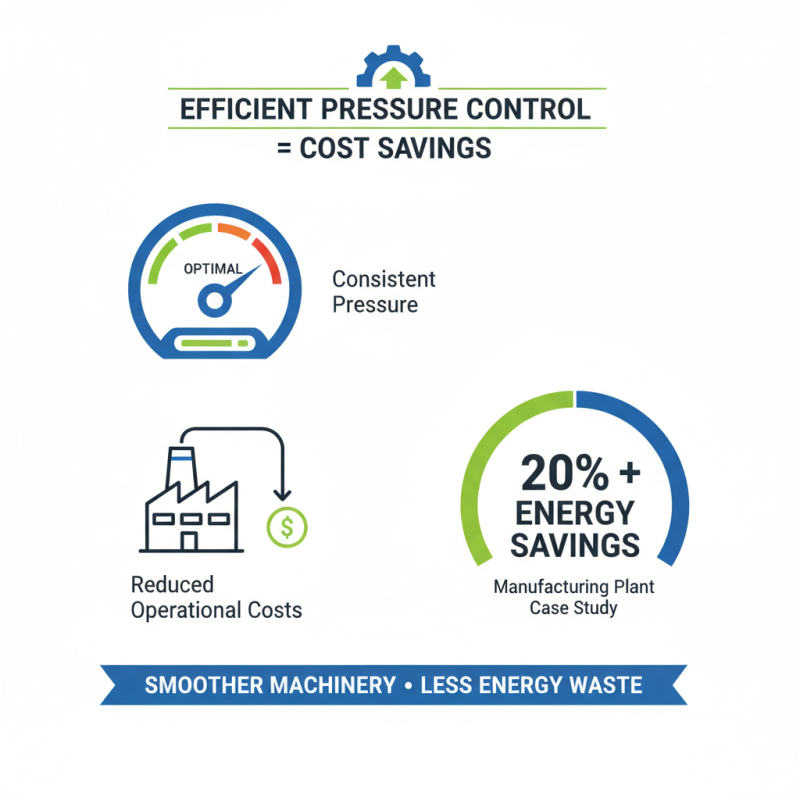

Case Studies: Impact of Efficient Pressure Control on Operational Costs

Efficient pressure control can significantly influence operational costs. Companies that implement effective pressure control systems often see notable savings. For example, in one case study, a manufacturing plant reduced energy expenses by over 20%. This reduction stemmed from maintaining optimal pressure levels in their hydraulic systems. When pressure is consistent, machinery runs smoothly and uses less energy.

However, not all systems deliver the same results. Some facilities still struggle with outdated pressure control methods. Poor pressure regulation can lead to equipment malfunctions and increased maintenance costs. A food processing plant faced this issue, experiencing frequent breakdowns due to improper pressure settings. Their operational costs soared as a result.

The lesson is clear: investing in modern pressure control valves is crucial. Companies need to assess their current systems regularly. Gathering data on pressure variations can reveal areas for improvement. Small changes can pave the way for significant savings over time. Organizations must reflect on their practices to avoid loss and inefficiency in their operations.

Related Posts

-

Top 5 Relief Valve Options for Optimal Pressure Control in Industrial Applications

-

2026 How to Choose the Right Safety Relief Valve for Your System?

-

Why is a Pressure Relief Valve Essential for Safety?

-

Exploring the Benefits of Installing a Water Pressure Relief Valve in Your Home Plumbing System

-

Top 10 Benefits of Using Globe Valves in Industrial Applications

-

Top 5 Asco Solenoid Applications and Benefits You Need to Know