How to Choose the Right Asco Solenoid Valve for Your Application

When it comes to selecting the right component for fluid control systems, the asco solenoid valve stands out as a crucial element in various applications. The versatility and reliability of these valves make them an integral part of numerous industries, from manufacturing to HVAC and beyond. Understanding the specific requirements of your application is essential for making an informed choice that ensures efficiency and safety.

In this guide, we will explore key considerations for choosing the appropriate asco solenoid valve, including flow characteristics, pressure ratings, and operating environments. By delving into the unique features and benefits offered by different models, users can navigate the complexities of valve selection and optimize their systems for maximum performance. Whether you are dealing with simple on/off functions or more complex control requirements, grasping these fundamentals will aid in selecting the ideal solenoid valve for your needs.

Understanding Asco Solenoid Valves and Their Applications

Asco solenoid valves are essential components in various industrial applications, and understanding their functionality and uses is crucial for selecting the right type for a specific need. These valves work by controlling the flow of liquids or gases in pneumatic and hydraulic systems through the use of electromagnetic coils. They are commonly used in manufacturing processes, irrigation systems, and HVAC applications. According to the Global Solenoid Valve Market report, the market is projected to grow at a compound annual growth rate (CAGR) of 4.8% from 2021 to 2026, driven by the increasing demand for automated systems across industries.

When selecting a solenoid valve, it’s vital to consider several factors, including pressure ratings, media type, and environmental conditions. For instance, valves designed for water applications may not be suitable for corrosive substances. A recent industry survey highlighted that about 30% of valve-related failures in automation projects stem from incorrect valve selection. Therefore, understanding the specific parameters, such as voltage requirements and operational lifespan, can significantly enhance performance and reliability in any application. Proper assessment ensures that the chosen valve not only meets immediate operational demands but also aligns with long-term objectives in efficiency and maintenance.

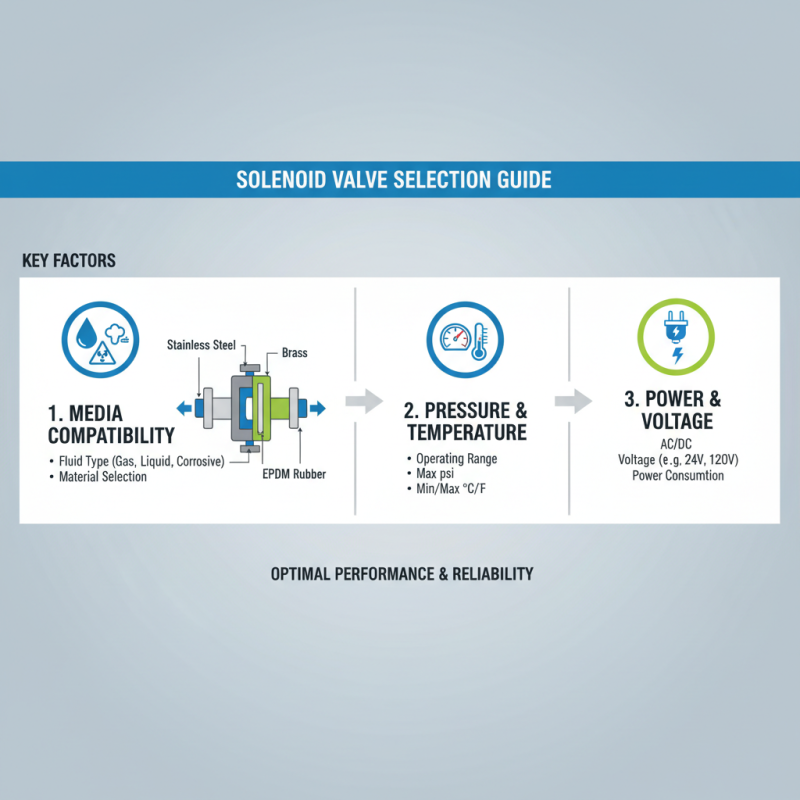

Key Factors to Consider When Selecting an Asco Solenoid Valve

When selecting the right solenoid valve for your application, several key factors come into play to ensure optimal performance and reliability. Firstly, consider the valve's media compatibility. The type of fluid—be it gas, liquid, or corrosive substances—greatly influences the material selection of the valve components. Ensuring that the valve materials can withstand the specific fluid's chemical properties is crucial to prevent failure or leaks.

Secondly, evaluate the operational environment where the valve will be installed. Factors such as temperature, pressure, and exposure to contaminants can affect the valve's functionality. It's important to choose a valve that can operate effectively within the required pressure ranges and temperature limits, as well as one that has adequate sealing mechanisms to protect against environmental factors. Additionally, assess the valve's voltage and response time characteristics to align with your system’s requirements, ensuring it meets the necessary actuation speed and electrical specifications for seamless integration into your operation.

Evaluating Compatibility with Fluid Type and Pressure Requirements

When selecting the appropriate solenoid valve for a specific application, evaluating compatibility with both fluid type and pressure requirements is crucial. Different fluids can have varied chemical properties, which may affect the performance and longevity of the valve. For instance, according to the Fluid Control Industry Report (2023), compatibility with the fluid is a key factor in preventing corrosion and ensuring the valve functions effectively over its intended lifespan. When dealing with aggressive chemicals, the choice of actuator materials and seal types can significantly influence operational efficiency.

In addition to fluid compatibility, understanding the pressure requirements is essential to ensure optimal performance. The pressure tolerance of the solenoid valve must align with the operational environment to prevent operational failures. A study published in the Journal of Fluid Mechanisms (2022) indicates that improperly rated solenoid valves can lead to significant operational risks, including leakage and system failures. Therefore, precisely matching the valve's pressure rating with the expected pressure conditions is vital to maintaining system integrity. This careful evaluation process can greatly enhance reliability and functionality across various applications.

Asco Solenoid Valve Performance Evaluation

Assessing the Electrical Specifications and Control Options

When selecting the right solenoid valve for your application, understanding the electrical specifications is paramount. The voltage and current requirements must align with your system to ensure optimal operation. Solenoid valves typically operate at various voltage levels – common options include 12V, 24V, and 120V. It is essential to consider the power supply available in your application, as mismatched specifications can lead to inefficiencies or malfunctions. Furthermore, the coil resistance and power consumption should be evaluated to understand how they impact the overall energy efficiency of the system.

In addition to voltage considerations, control options play a significant role in choosing the appropriate solenoid valve. Depending on your application, you may require a normally closed or normally open valve, which influences how the valve responds to electrical signals. Assessing the response time and maximum frequency of operation is also critical, especially in high-speed applications where timely actuation is necessary. Additionally, explore whether manual override or remote control options enhance flexibility in controlling the valve, allowing for greater adaptability to changing operational demands.

How to Choose the Right Asco Solenoid Valve for Your Application - Assessing the Electrical Specifications and Control Options

| Valve Type | Voltage | Wattage | Control Options | Media Compatibility |

|---|---|---|---|---|

| Direct Acting | 24 V DC | 6 W | On/Off Control | Water, Air |

| Pilot Operated | 120 V AC | 10 W | Continuous Duty | Oil, Gas |

| Solenoid Valve with Manual Override | 12 V DC | 3 W | On/Off with Override | Air, Water |

| Normally Closed | 24 V AC | 5 W | Proportional Control | Steam, Air |

Common Applications for Asco Solenoid Valves in Various Industries

Asco solenoid valves are integral components in numerous industries due to their versatility and reliability. Common applications span across sectors such as manufacturing, water treatment, and HVAC systems. In the manufacturing industry, solenoid valves play a crucial role in automation processes, controlling the flow of gases and liquids with precision. According to a report by MarketsandMarkets, the global market for solenoid valves is projected to reach USD 6.7 billion by 2025, underlining their significance in enhancing operational efficiencies.

In water treatment facilities, Asco solenoid valves facilitate the management of water flow in filtration and chemical dosing systems. This is critical as these systems help ensure safe and clean water is delivered to communities. The American Water Works Association highlights that efficient valve systems can improve treatment plant performance by up to 25%, reducing both operational costs and environmental impact.

Similarly, in HVAC applications, solenoid valves are essential for controlling fluid within heating and cooling systems. The increasing demand for energy-efficient HVAC systems has driven advancements in solenoid valve technology, making them vital for optimizing energy consumption. The International Energy Agency has noted that efficient HVAC systems can lower energy use by 30% to 50%, demonstrating the critical role these valves play in supporting sustainability initiatives across various industries.

Related Posts

-

2025 Top 5 Control Valve Trends Driving Efficiency in Industrial Applications

-

Exploring ASCO Solenoids: The Backbone of Modern Automation in Industries

-

2025 Guide: How to Choose the Perfect Dresser Utility for Your Space

-

Understanding Natural Gas Valves: Essential Guide to Safety and Efficiency in Your Home

-

Maximizing Efficiency with Asco Solenoids in Modern Automation Systems

-

How to Effectively Locate and Operate a Shut Off Valve in Your Home