Why is a Pressure Relief Valve Essential for Safety?

In industrial settings, safety is paramount. A pressure relief valve plays a critical role in maintaining safety during operations. According to a report by the American Society of Mechanical Engineers, improper pressure management can lead to serious failures. In fact, nearly 30% of industrial accidents result from overpressure incidents.

Pressure relief valves are designed to automatically release pressure. They prevent dangerous situations by managing excess pressure in systems. However, many facilities underestimate their importance. A study shows that nearly 40% of pressure relief valves fail to operate effectively due to neglect. This oversight can lead to catastrophic events, including explosions.

Regular maintenance and proper installation of pressure relief valves cannot be overstated. These valves must be tailored to specific applications to perform effectively. Neglecting such measures can lead to dire consequences. Organizations should prioritize investing in robust safety systems. Only then can they safeguard personnel and property from the dangers of uncontrolled pressure.

Importance of Pressure Relief Valves in Industrial Safety

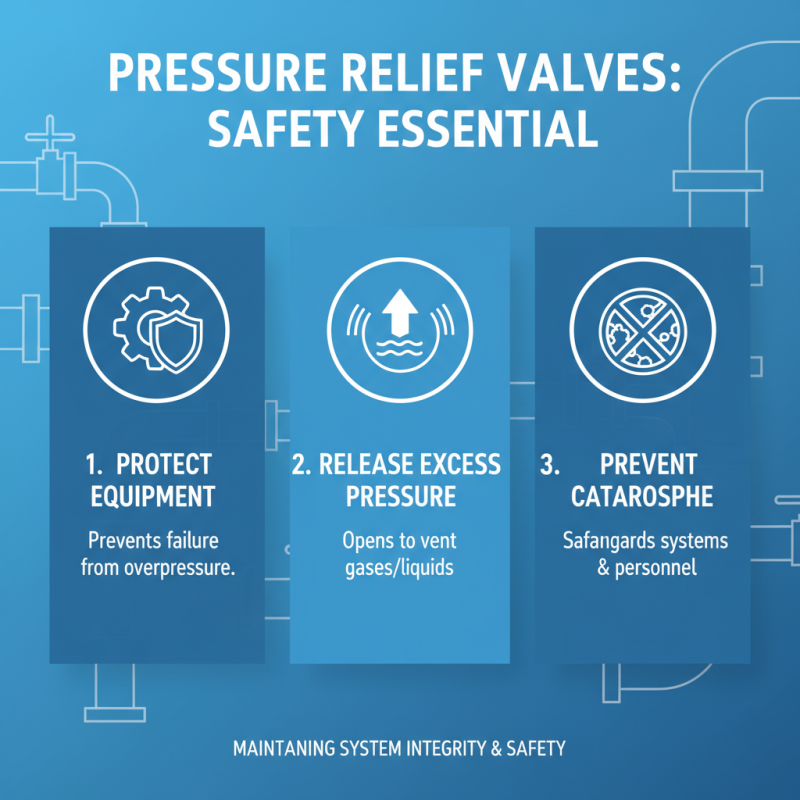

Pressure relief valves (PRVs) play a crucial role in industrial safety. They help prevent dangerous pressure build-up in systems. This component releases excess pressure, ensuring that equipment operates within safe limits. Without PRVs, systems can face catastrophic failures. Equipment could rupture, leading to injuries and significant damage.

Understanding the importance of PRVs is vital for any operation. Regular maintenance is key, as a faulty valve can compromise safety. Check for leaks or signs of wear. This can save lives and resources.

Tips: Always conduct pressure tests periodically. Implement a routine inspection schedule for all safety components. Train staff to recognize warning signs of valve malfunction. A proactive approach can prevent serious accidents. Invest time in training your team. An informed workforce is your best defense against safety risks.

Why is a Pressure Relief Valve Essential for Safety? - Importance of Pressure Relief Valves in Industrial Safety

| Dimension | Description | Importance | Typical Applications |

|---|---|---|---|

| Set Pressure | The pressure at which the relief valve is activated. | Prevents equipment damage by releasing excess pressure. | Boilers, pressure vessels. |

| Flow Capacity | The maximum flow rate through the valve when it opens. | Ensures sufficient discharge to prevent overpressure scenarios. | Pipelines, refineries. |

| Material | The materials used to construct the valve. | Durable materials are essential to withstand corrosive environments. | Chemical processing, oil and gas sectors. |

| Testing and Maintenance | Regular testing to ensure reliability and functionality. | Critical for operational safety and compliance with standards. | Manufacturing plants, water treatment facilities. |

| Regulatory Compliance | Adherence to safety standards and regulations. | Ensures workplace safety and avoids legal penalties. | All industrial sectors. |

Functionality of Pressure Relief Valves in Preventing Equipment Failure

Pressure relief valves play a critical role in maintaining safety in various systems. They help to prevent equipment failure by releasing excess pressure. When pressure builds up beyond a safe limit, these valves open to allow gases or liquids to escape. This release prevents catastrophic failures, protecting both the equipment and the operators.

Imagine a boiler with a malfunctioning pressure relief valve. If the valve fails, the pressure might skyrocket, leading to potential explosions or equipment destruction. Such incidents are not uncommon. Regular maintenance of pressure relief valves is vital, yet often overlooked. Operators might forget to check these valves regularly, assuming they will work perfectly. This assumption can be dangerous.

In certain applications, the consequences of a pressure relief valve failing to engage can be severe. Equipment can break down, causing costly repairs and downtime. It’s crucial to reflect on the design and implementation of these safety devices. Perhaps we need to innovate further to enhance their reliability. Even small details like valve size and placement can significantly impact their functionality. Therefore, careful consideration and regular assessments of pressure relief valves are essential for ensuring overall safety.

Types of Pressure Relief Valves and Their Specific Applications

Pressure relief valves (PRVs) are crucial in various applications. Different types serve specific needs. For instance, spring-loaded valves are commonly used in pipelines. They open automatically when pressure exceeds a set limit. This type is reliable and widely accepted in the industry.

Another type is the pilot-operated valve. It uses a smaller valve to control a larger one. These valves offer precise pressure control. They are ideal for high-pressure systems. Their design minimizes leakage and improves efficiency.

Tips: Regular maintenance is vital. Inspect the valves for wear and tear. Ensure they can operate under various conditions. Additionally, keep spare parts available. This can prevent unexpected downtime and improve safety.

Common Causes of Pressure Build-Up and Risks Without Relief Valves

A pressure relief valve is crucial for maintaining safety in any pressurized system. Pressure build-up often occurs due to temperature fluctuations, equipment malfunctions, or excessive fluid flow. These conditions can lead to dangerous situations and equipment failure if not properly managed.

Pressure spikes can cause explosions or leaks, resulting in severe injuries or costly damages. That's why installing a pressure relief valve is a proactive step every system owner should consider. Without it, a minor issue could escalate quickly.

Tips: Regular inspections are key. Check your pressure relief valves frequently. Build-ups can occur suddenly, so don’t wait for problems to arise.

Another tip is to ensure proper sizing and installation of the valve. An improperly sized valve can fail to relieve pressure as intended, leading to potential disasters.

Remember, it’s the small details that can make a difference. A loose connection or worn-out part can compromise safety. Always stay vigilant and maintain your equipment.

Maintenance Practices for Ensuring Pressure Relief Valve Efficiency

Pressure relief valves play a crucial role in safety. They prevent excessive pressure buildup in various systems. However, to ensure they function effectively, regular maintenance is necessary. Neglecting this might lead to unforeseen accidents.

Regular inspections should be a priority. Technicians need to check for visible leaks and corrosion. A minor issue can escalate quickly. Testing the valve’s functionality should happen at scheduled intervals. If it doesn't open at the set pressure, it could fail when needed. Records of these tests must be kept for accountability.

Cleaning is also vital but often overlooked. Dirt can hinder performance. A simple wash can make a difference. Ensure all moving parts are lubricated. Sometimes, manufacturers provide detailed maintenance guidelines. Following these can prevent failures. However, each environment is unique. Tailoring maintenance to specific conditions is essential. Regular training for staff is necessary too. They should understand the potential consequences of a malfunction. Taking these steps can enhance safety substantially.

Pressure Relief Valve Efficiency Over Time

This chart illustrates the efficiency of pressure relief valves over a 12-month period, highlighting the importance of regular maintenance practices in ensuring safety. The data reflects typical efficiency percentages recorded during routine checks and inspections.

Related Posts

-

Understanding Pressure Relief Valves: Key Specifications and Their Crucial Role in Industrial Safety

-

Exploring ASCO Solenoids: The Backbone of Modern Automation in Industries

-

How to Locate and Use a Natural Gas Shut Off Valve Safely

-

Maximizing Efficiency with Asco Solenoids in Modern Automation Systems

-

How to Choose the Right Automatic Valve for Your Industrial Needs

-

2025 Top 5 Control Valve Trends Driving Efficiency in Industrial Applications